Product classification

Contact Us

E-mail

hm@heatmatetech.com

Service Hotline:

400-812-2880

Biomedical Cold-Chain Transportation Solution

Key words:

Classification:

Product Details

Biomedical Cold-Chain Transportation Solution

Biomedical Cold-Chain Transportation Solution is one of the core applications of Heatmate's self-developed phase-change materials. We can provide a complete solution for long time temperature control of biomedical products in the range of -80~30℃.

Product Type

Core advantages

Customizable Design

Phase-change material and case dimension can be tailored to the customers' needs

Custom-made Control Temperature

Core material development technology provides phase-change materials for various temperature points between -80 to 30℃.

Temperature Control Precision

Maintains a constant temperature when releasing cold, significantly enhancing cargo stability.

Long-lasting

The increased cold storage capacity can support long-time transportation requirements.

Safety And Environmental Friendliness

Food-grade plastic packaging is odorless, non-toxic, and meets safety standards for both pharmaceuticals and food.

Portability

Compact packaging for easy transportaation.

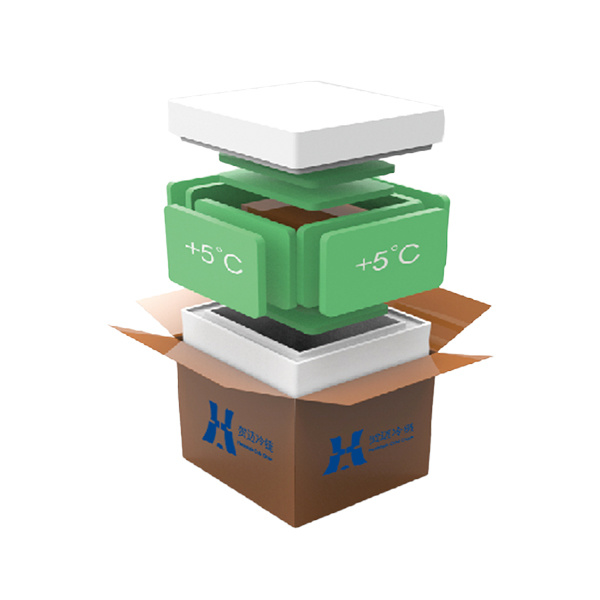

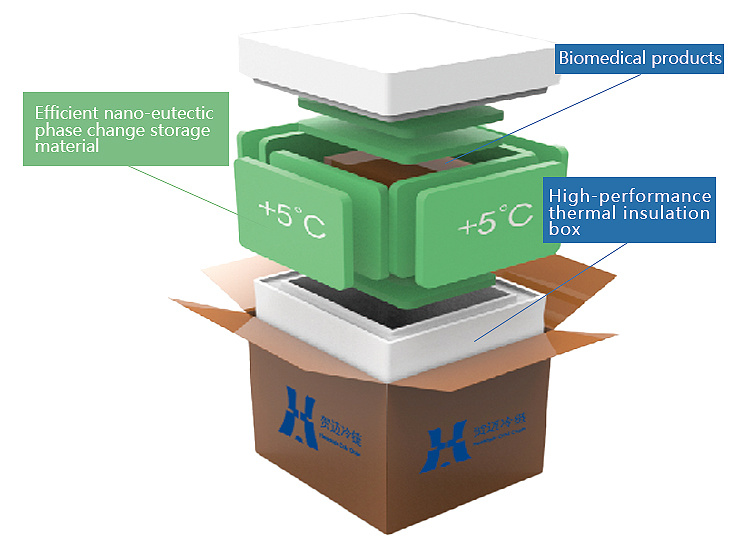

System components

01 Core Technology

The phase-change materials used in the phase change thermal storage are developed by Heatmate and is featured by custom temperatures, stable performance, high energy storage density, and green safety.

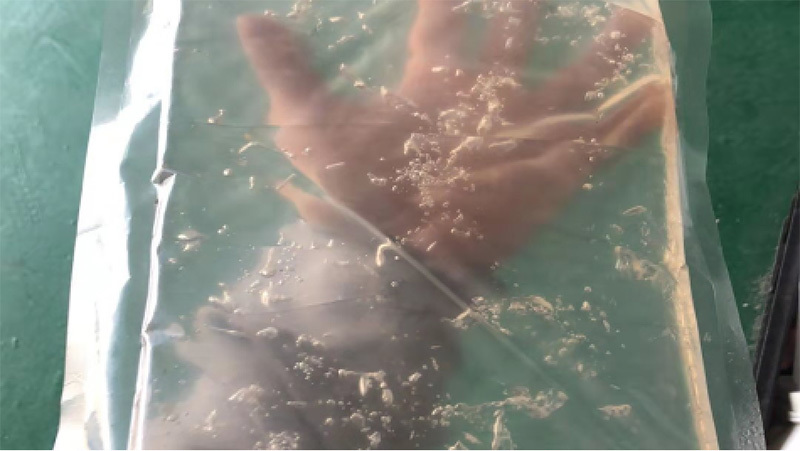

02 Customisable PCM Encapsulation

HDPE Encapsulation: Non-toxic, odorless, with high strength that can withstand mechanical impact. Suitable for general transportation.

PCM crystal film: Solid-solid phase-change material, saving encapsulation space. Small footprint, no risk of leakage, suitable for air transportation.

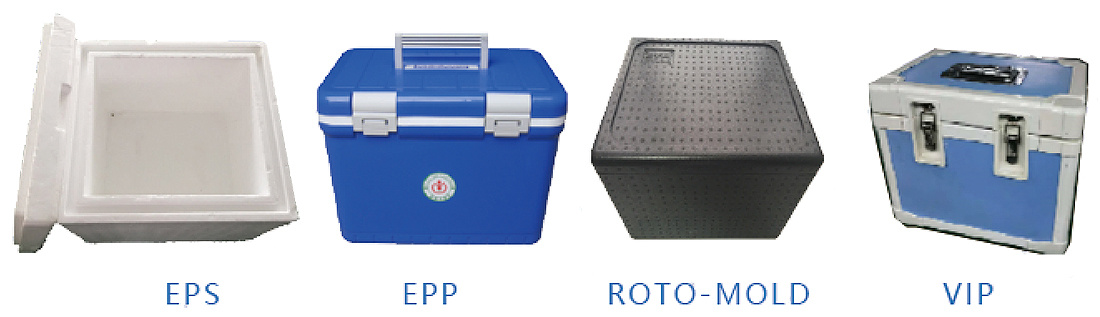

03 Customization OfInsulation Box

The outer box can be deeply customized according to customer needs, including cost-effective options such as EPS and EPP insulation boxes, high-strength roto-molded insulation boxes, and custom VP insulation boxes.

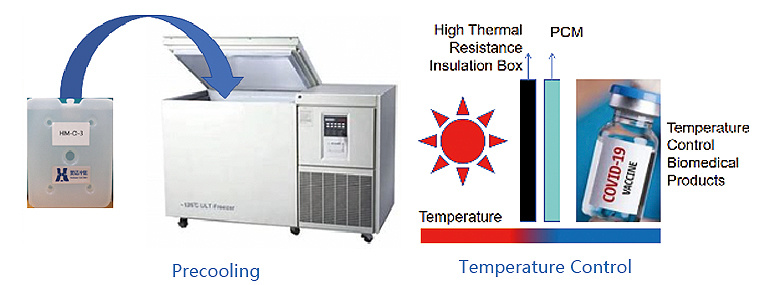

Working principle

Precooling

Precool the phase-change ice box to the control temperature required by the product before use

Temperature Control

Place the phase-change ice boxes around temperature-sensitive biomedical products to continuously maintain their temperature within the desired limits

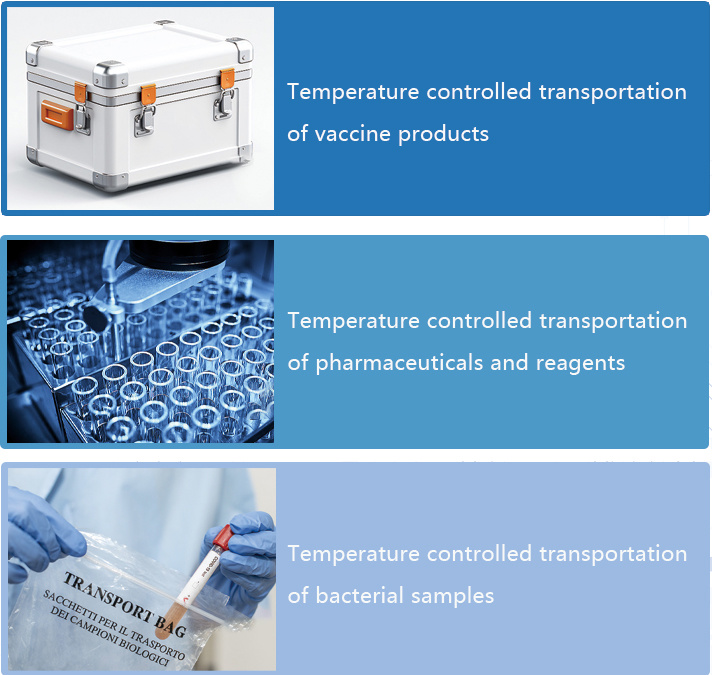

Application scenarios

Previous Page:

Next page:

Product inquiry

* Please leave your phone number and we will contact you within 24 hours!