The Critical Role of Temperature Control in Mobile Container Cold Storage Solutions

2026-01-14

The Critical Role of Temperature Control in Mobile Container Cold Storage Solutions

Table of Contents

1. Introduction to Mobile Container Cold Storage

2. Why Temperature Control is Vital

2.1 Maintaining Product Integrity

2.2 Ensuring Regulatory Compliance

2.3 Enhancing Supply Chain Efficiency

3. Technologies Used in Mobile Cold Storage

4. Ch

The Critical Role of Temperature Control in Mobile Container Cold Storage Solutions

Table of Contents

- 1. Introduction to Mobile Container Cold Storage

- 2. Why Temperature Control is Vital

- 2.1 Maintaining Product Integrity

- 2.2 Ensuring Regulatory Compliance

- 2.3 Enhancing Supply Chain Efficiency

- 3. Technologies Used in Mobile Cold Storage

- 4. Challenges in Temperature Control

- 5. Best Practices for Effective Temperature Management

- 6. Case Studies: Real-World Applications

- 7. The Future of Temperature-Controlled Solutions

- 8. FAQs

- 9. Conclusion

1. Introduction to Mobile Container Cold Storage

In today’s fast-paced world, **mobile container cold storage** has emerged as a crucial solution for industries that require precise temperature management. From pharmaceuticals to food services, businesses are increasingly relying on mobile cold storage units to safeguard perishable goods during transport and storage. This article delves deep into the critical importance of temperature control within these mobile systems and how it can influence product quality and operational efficiency.

2. Why Temperature Control is Vital

2.1 Maintaining Product Integrity

Temperature fluctuations can severely compromise the integrity of sensitive products. For instance, in the food industry, improper temperature management can lead to spoilage, affecting both safety and quality. Similarly, pharmaceuticals require stringent temperature control to prevent degradation of active ingredients. By utilizing **mobile container cold storage**, businesses can ensure consistent temperature levels, thus preserving the integrity and safety of their products.

2.2 Ensuring Regulatory Compliance

Many industries are governed by strict regulations regarding temperature control. For example, the FDA mandates specific temperature ranges for the storage and transport of pharmaceutical products. Failure to comply can result in significant legal repercussions and financial losses. Mobile container cold storage provides a viable solution to meet these regulatory requirements, ensuring that products are handled according to industry standards.

2.3 Enhancing Supply Chain Efficiency

Efficient temperature control in cold storage not only protects products but also streamlines the entire supply chain. When temperature fluctuations are minimized, businesses can reduce waste, lower operational costs, and improve customer satisfaction by ensuring timely delivery of high-quality goods. Mobile solutions allow for flexibility, enabling companies to adapt quickly to changing demands and maintain a competitive edge.

3. Technologies Used in Mobile Cold Storage

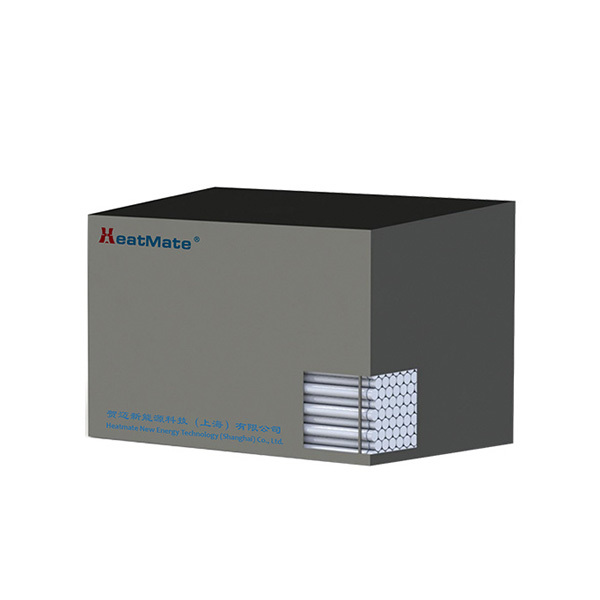

The advancement of technology has significantly enhanced the effectiveness of **mobile container cold storage**. Various systems and devices help maintain optimal temperatures and monitor conditions throughout the storage process.

3.1 Temperature Monitoring Systems

Modern mobile cold storage units are often equipped with sophisticated **temperature monitoring systems** that provide real-time data on internal conditions. This allows operators to make quick adjustments as needed and helps in maintaining compliance with regulatory standards.

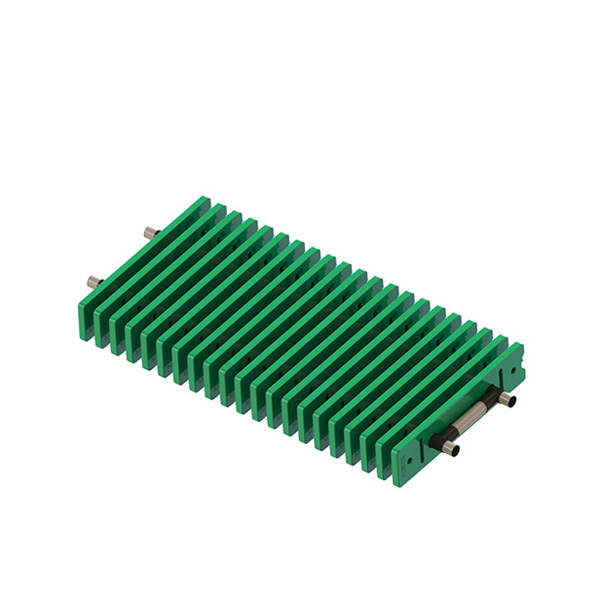

3.2 Insulation Technologies

High-quality insulation materials play a pivotal role in minimizing temperature fluctuations. Insulated mobile containers help retain cold air while preventing external temperatures from affecting the internal environment, ensuring that products remain at the desired temperature range.

3.3 Advanced Refrigeration Solutions

Innovative refrigeration technologies, such as compressor-driven and passive cooling systems, are essential for effective temperature control in mobile cold storage. These systems are designed to operate efficiently, reducing energy consumption while maintaining optimal temperatures.

4. Challenges in Temperature Control

Despite advancements in technology, several challenges persist in maintaining temperature control in mobile container cold storage.

4.1 Environmental Factors

External environmental conditions, such as extreme heat or cold, can significantly impact the effectiveness of mobile storage units. Companies must adopt strategies to mitigate these challenges, such as using reflective materials or positioning units in shaded areas.

4.2 Equipment Malfunction

Equipment failures can lead to costly temperature excursions. Regular maintenance and employing backup systems can help mitigate these risks, ensuring that mobile cold storage units operate efficiently at all times.

5. Best Practices for Effective Temperature Management

To achieve optimal temperature control in mobile container cold storage, businesses must implement a set of best practices.

5.1 Regular Monitoring and Data Logging

Implementing regular monitoring processes and using data logging devices can help track temperature variations over time. This data is invaluable for identifying trends and making informed decisions to improve cold storage practices.

5.2 Staff Training and Awareness

Educating staff on the importance of temperature control is crucial. Training programs should emphasize proper handling procedures, protocols for checking temperature, and the importance of reporting anomalies immediately.

5.3 Emergency Preparedness Plans

Developing emergency plans to address potential temperature control failures is essential. Businesses should have protocols in place for quick response actions and backup solutions to minimize risks during unforeseen circumstances.

6. Case Studies: Real-World Applications

Examining real-world applications of mobile container cold storage illustrates its impact across various industries.

6.1 The Food Industry

A leading food distributor implemented mobile cold storage solutions to manage the delivery of perishable items. By utilizing temperature monitoring systems and insulated containers, they reduced spoilage rates by 30%, significantly improving overall efficiency.

6.2 The Pharmaceutical Sector

A pharmaceutical company faced challenges in transporting temperature-sensitive drugs. By switching to mobile container cold storage and instituting rigorous temperature control protocols, they ensured compliance with FDA regulations, avoiding costly penalties and safeguarding patient health.

7. The Future of Temperature-Controlled Solutions

As technology continues to evolve, the future of mobile container cold storage looks promising. Innovations in IoT, machine learning, and smart sensors are paving the way for even more robust solutions that promise to enhance temperature control and operational efficiency.

8. FAQs

8.1 What is mobile container cold storage?

Mobile container cold storage refers to portable refrigeration units designed to maintain specific temperature ranges for sensitive goods during transport and storage.

8.2 Why is temperature control important in cold storage?

Effective temperature control is critical for preserving product integrity, ensuring compliance with regulations, and improving supply chain efficiency.

8.3 What technologies are used in mobile cold storage?

Technologies include temperature monitoring systems, advanced refrigeration solutions, and high-quality insulation materials.

8.4 How can businesses improve temperature management practices?

Businesses can enhance practices by implementing regular monitoring, staff training, and emergency preparedness plans.

8.5 What challenges do companies face in maintaining temperature control?

Challenges include environmental factors, equipment malfunction, and the need for robust monitoring systems.

9. Conclusion

In conclusion, **temperature control** in **mobile container cold storage** is not merely a logistical requirement but a critical component for safeguarding product quality, ensuring regulatory compliance, and enhancing operational efficiency. With the right technologies, best practices, and a proactive approach to challenges, businesses can reap the benefits of effective cold storage solutions. As industries continue to evolve and demand for perishable goods increases, prioritizing temperature management will be essential for maintaining competitiveness in the marketplace.

Key words:

Related News

The Future of Cold Storage: Phase Change Technology Explained

The Future of Cold Storage: Phase Change Technology Explained

Table of Contents

Introduction to Cold Storage and Its Importance

What is Phase Change Technology?

How Phase Change Technology Works

Applications of Phase Change Technology in Cold Storage

Benefits of Using Phase Change Materials (PCMs)

Challenges and Limitations of Phase Change Technology

The Future of Cold

2026-02-04

Understanding Phase Change Heating: A Key to Sustainable Energy Solutions

Phase change heating is an innovative technology that utilizes the unique properties of materials as they transition between solid and liquid states to store and release energy efficiently. This concept is gaining significant traction in the renewable energy sector, particularly in applications related to metallurgy and minerals, where energy efficiency and sustainability are paramount.

At its cor

2026-01-30

Maximizing Comfort: The Benefits of Outdoor Heating Equipment for Your Space

Maximizing Comfort: The Benefits of Outdoor Heating Equipment

Table of Contents

1. Understanding Outdoor Heating Equipment

2. The Importance of Outdoor Comfort

3. Types of Outdoor Heating Equipment

3.1 Patio Heaters

3.2 Fire Pits

3.3 Infrared Heaters

3.4 Outdoor Fireplaces

3.5 Electric and Gas Heaters

4. Benefits of Using Outdoor Heating Equipment

4.1 Extended Outdoor Living

2026-01-24